Home

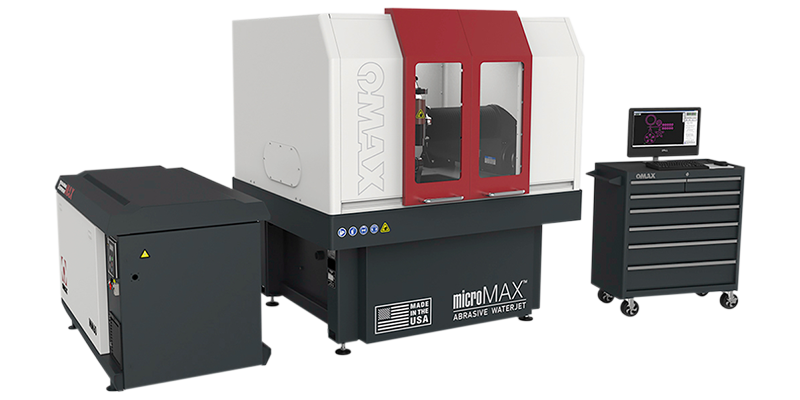

Superior Machine Tool Technologies

With over 60 years of experience serving the Utah, Idaho, Wyoming, Montana and Alaska manufacturing markets, Smith Machinery Company is uniquely qualified to support and help manufacturers grow in the metal cutting industry. The team at Smith Machinery are professionals at recommending the best available technology to help solve the challenges of today’s manufacturing environment.

Smith Machinery

Smith Machinery